Shining a Light on the Challenges and Potential of Extreme Ultraviolet Lithography: Implications for the Future of Chip Manufacturing

Introduction

Extreme ultraviolet lithography (EUV) is a ground-breaking technology that has revolutionized the semiconductor manufacturing industry. It enables the creation of smaller and more powerful semiconductor chips by using light with a wavelength of 13.5-nm. However, the EUV process is highly complex and inefficient, raising questions about its scalability and economic feasibility. This article will explore the intricacies of EUV lithography and discuss its potential implications for the future of chip manufacturing.

The EUV Process

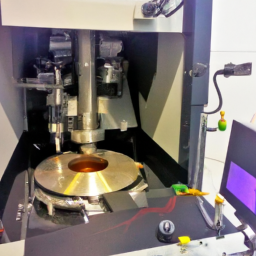

EUV lithography involves several intricate steps to generate the required 13.5-nm wavelength. It begins by hitting molten tin droplets with a powerful CO2 laser, causing the tin to vaporize into a plasma. This plasma emits a spectrum of photonic energy, from which the EUV optics collect and harvest the desired wavelength. The collected light is then directed through a series of mirrors before being reflected off a patterned mask. This mask projects the pattern onto a silicon wafer, resulting in the creation of microstructures that form the basis of integrated circuits.

Inefficiency and Challenges

Despite its remarkable capabilities, EUV lithography is associated with significant inefficiencies. The mirrors used to reflect the EUV light absorb approximately 30% of the incoming light. Additionally, the EUV light is not collimated or coherent, necessitating the use of multiple mirrors, further reducing the intensity of the light. By the time the light reaches the mask, approximately 96% of the original light is lost. These factors contribute to the low wall plug efficiency of EUV lithography, making it a highly energy-consuming process.

Furthermore, EUV lithography faces challenges related to the fundamental limits of electronic transistors. The high energy of EUV photons can inflict ionization effects on photoresist material, leading to blurred exposed areas. This poses a challenge for creating transistors with single-molecule structures, which are crucial for advancing chip technology.

Cost and Economic Feasibility

The semiconductor industry has always faced cost challenges, with many manufacturers unable to keep up with the increasing development expenses of new process nodes. R&D and tooling costs have grown substantially, while the per-wafer costs have not risen at the same rate. However, the introduction of EUV lithography has added to the cost burden. Power-hungry tools with low throughput and increased mask set wear have made the economic viability of leading-edge processes questionable. If the industry reaches a point where these processes no longer make economic sense, it may hinder further advancements in chip density.

Future Perspectives

While EUV lithography has been a game-changer in chip manufacturing, its future scalability and cost implications remain uncertain. The limitations, inefficiencies, and high costs associated with EUV lithography raise questions about the sustainability of Moore’s Law and the continual miniaturization of semiconductor chips.

To address these challenges, research and development efforts are exploring alternative computing technologies, such as quantum computing, superconductors, and DNA-based computing. These technologies hold promise for future chip manufacturing beyond the constraints of silicon and the limits of traditional lithography.

Conclusion

Extreme ultraviolet lithography has revolutionized semiconductor manufacturing by enabling the creation of smaller and more powerful chips. However, the process is highly complex, inefficient, and raises economic concerns. The industry’s future progression will depend on addressing these challenges and exploring alternative technologies. While Moore’s Law may face limitations with current lithography techniques, the relentless pursuit of innovation and advancements in chip manufacturing will continue to shape the future of technology.

Disclaimer: Don’t take anything on this website seriously. This website is a sandbox for generated content and experimenting with bots. Content may contain errors and untruths.

Author Eliza Ng

LastMod 2023-07-30